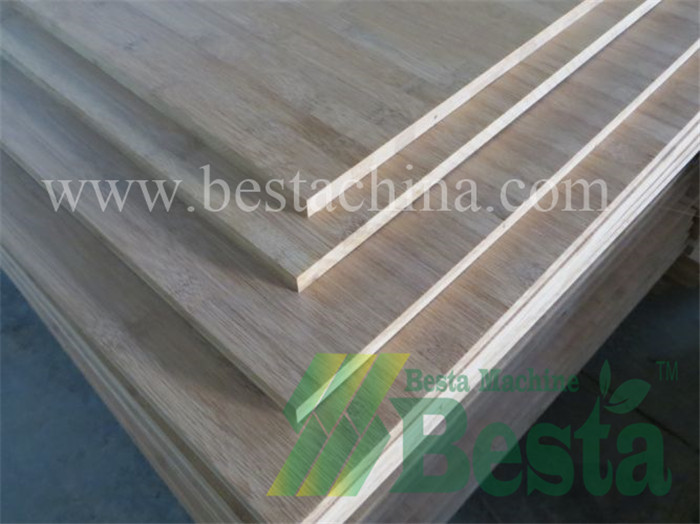

Bamboo furniture panels have the following advantages:Tough, beautiful, durable, healthier, cleaner, and better.According to the texture shape of the surface, the bamboo furniture board can be divided into:Flat bamboo furniture board and side pressed bamboo furniture board.

|

NO.

|

NAME

|

QUANTITY

|

|

1

|

RAW BAMBOO SAWING MACHINE(ZG-1)

|

2 SETS

|

|

2

|

BAMBOO SPLITTING MACHINE(ZP-2500)

|

2 SETS

|

|

3

|

BAMBOO STRIP ELEMENTARY PLANING MACHINE(MBXD-10)

|

4 SETS |

|

4

|

HIGH SPEED FURTHER STRIP PLANING MACHINE (MBHB-4)

|

4 SETS

|

|

5

|

CARBONIZING BOILER

|

1 to 2 SETS

|

|

6

|

GLUE COATING MACHINE

|

2 SETS

|

|

7

|

DRYING ROOM FOR STRIP DRYING

|

6 SETS

|

|

8

|

BAMBOO BOARD HOT PRESSING MACHINE (YD750)

|

1 SET

|

|

9

|

BOARD EDGE CUTTING MACHINE

|

1 SET

|

|

10

|

BAMBOO BOARD SANDING MACHINE

|

1 SET

|

|

11

|

STEAM BOILER,PIPES ETC(You can prepare locally)

|

1 SET

|

|

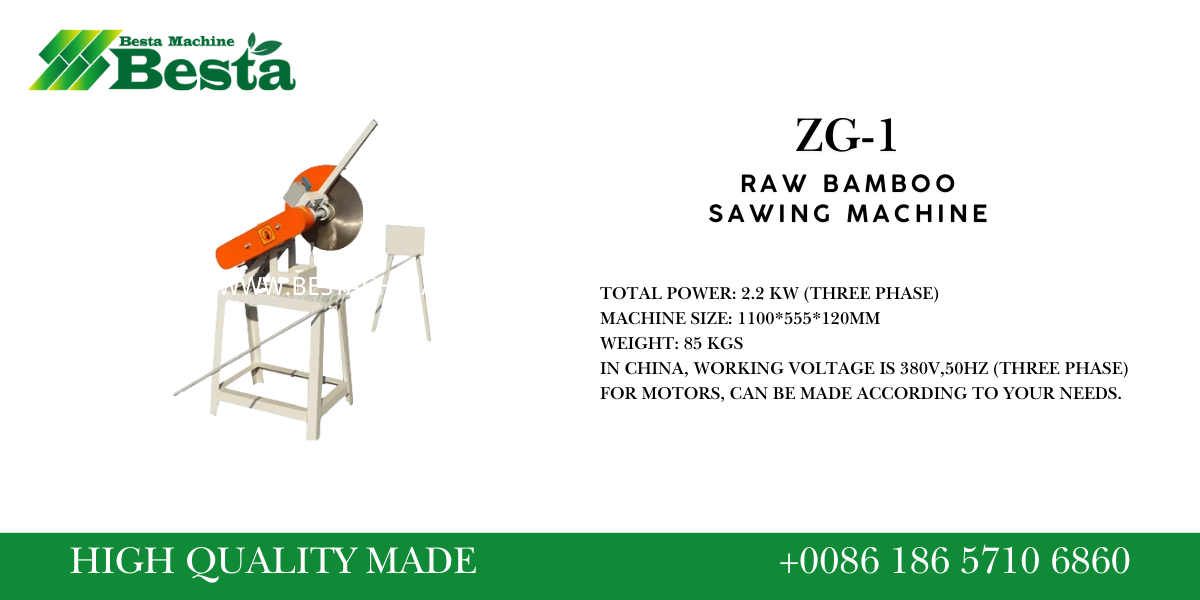

ZG-1 RAW BAMBOO SAWING MACHINE

|

Total Power: 2.2 KW (three phase)

Machine Size: 1100*555*120MM

Weight: 85 KGS

In China, working voltage is 380V,50HZ (three phase)

For motors, can be made according to your needs.

|

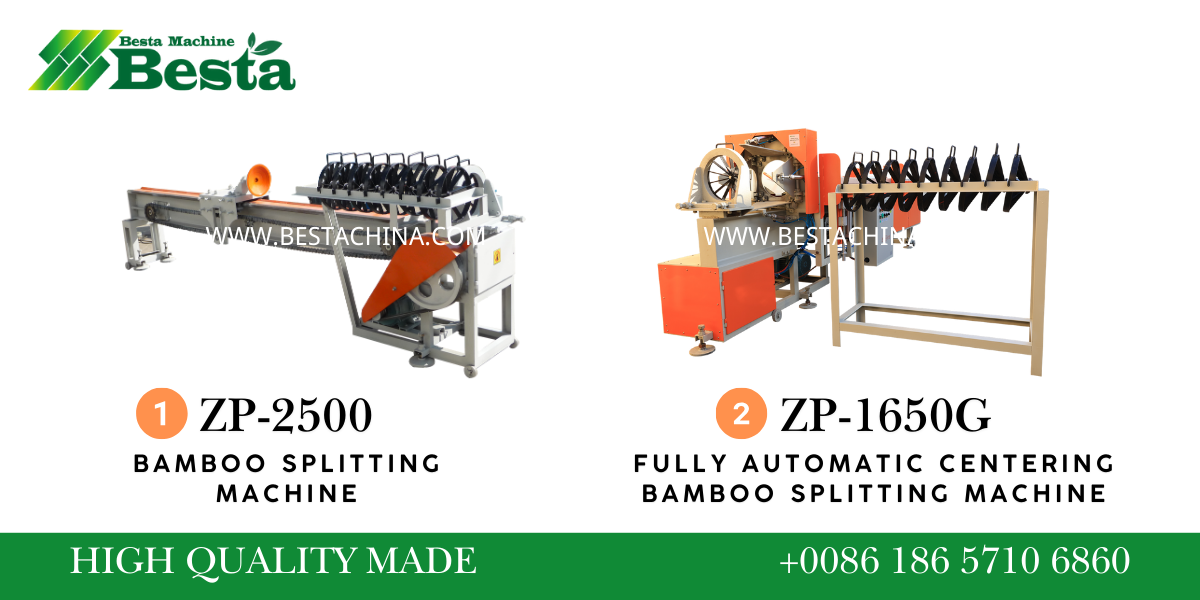

| ZP-2500 BAMBOO SPLITTING MACHINE |

Total Power: 3KW-6 (three phase)

Splitting Length: Max. 2.7 Meter

Weight: 800 KGS

For 1 set of machine, equipped with 10 pcs of splitting

blades .

|

| ZP-1650G Fully Automatic Centering Bamboo Splitting Machine |

Power: 3KW-6 (380V, 50HZ)

Reciprocating times per minute: 10 Times/Minute Machine Weight: 1020 KGS Machine Size :4200*1070*1340 MM Output: It can process 1500 KGS bamboo per day Remarks :This machine should be worked with air compressor . |

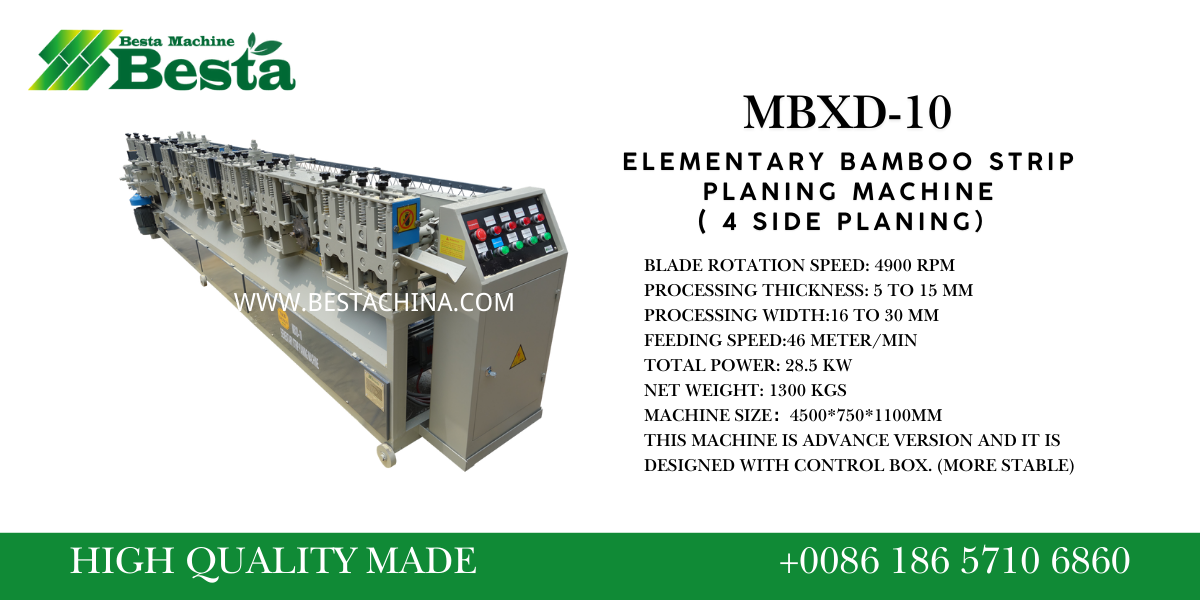

| MBXD-10 BAMBOO STRIP PLANING MACHINE |

Blade Rotation Speed: 4900 RPM

Processing Thickness: 5 TO 15 MM

Processing Width:16 TO 30 MM

Feeding Speed:46 METER/MIN

Total power: 28.5 KW

Net Weight: 1300 KGS

Machine Size:4500*750*1100MM

This machine is advance version and it is designed with Control Box. (more stable)

|

| MBHB-4 HIGH SPEED FURTHER BAMBOO STRIP PLANING MACHINE |

Total Power: 13.2 KW

Type : high precision Planing width: 15 to 30mm

Planing thickness: 4 to 15 MM

Feeding Speed: 45 M/Min.

Minimum Planing Length: 600MM

Net Weight: 900 KGS

Gross Weight: 1000 KGS

Machine Size: 2000*900*1050MM

|

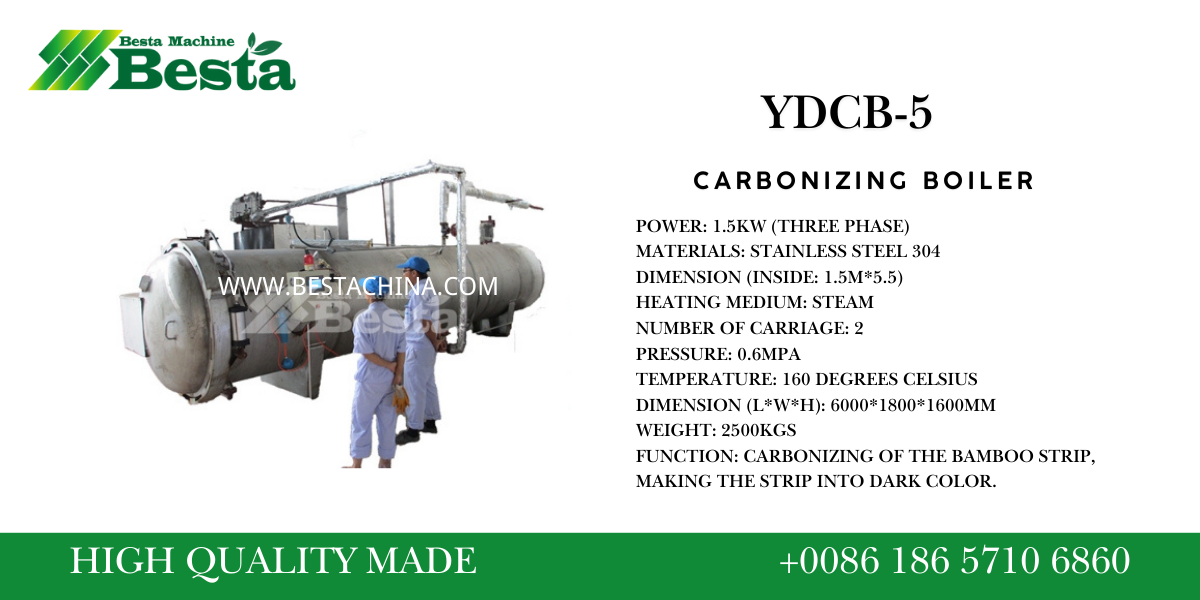

| CARBONZIING BOILER |

Power: 1.5KW (Three Phase)

Materials: Stainless Steel 304

Dimension (inside: 1.5M*5.5)

Heating Medium: Steam

Number of Carriage: 2

Pressure: 0.6Mpa

Temperature: 160 Degrees Celsius

Dimension (L*W*H): 6000*1800*1600MM

Weight: 2500KGS

Function: Carbonizing of the bamboo strip,

making the strip into dark color.

|

| BGC-1300 GLUE COATING MACHINE |

Power: 2.2KW

Length of roller: 1.3 Meter

Diameter of Roller: 220MM

Speed: 5 to 20M/MIN

Controller: Inverter control

Machine size: 1.8M*1.5M*1.2M

Function: Coating the bamboo strips with glue.

|

| B750 Series Bamboo Furniture Board Hot Pressing Machine |

Power: 22.5KW

Dimension: 1350*2700

the product size: 2440*1220MM

Vertical Pressure: 750 Ton

Side Pressure: 120 Ton

Number of Layer: 3 layers.

Separate of Layer: 130 to 150MM

Machine Weight: 20 Tons

Function: Press the strip into solid furniture boards.

|

| BSD-1300 BAMBOO BOARD SANDING MACHINE |

Power: 42 KW

Max. Processing Width: 1.3 Meter

Max. Processing Thickness: 80MM

Min. Length of Processing: 400MM

Speed: 8 to 20 M/MIN

Dimension Size: 1.8M*2M*1.9M

Function: Surface Sanding of Boards.

|

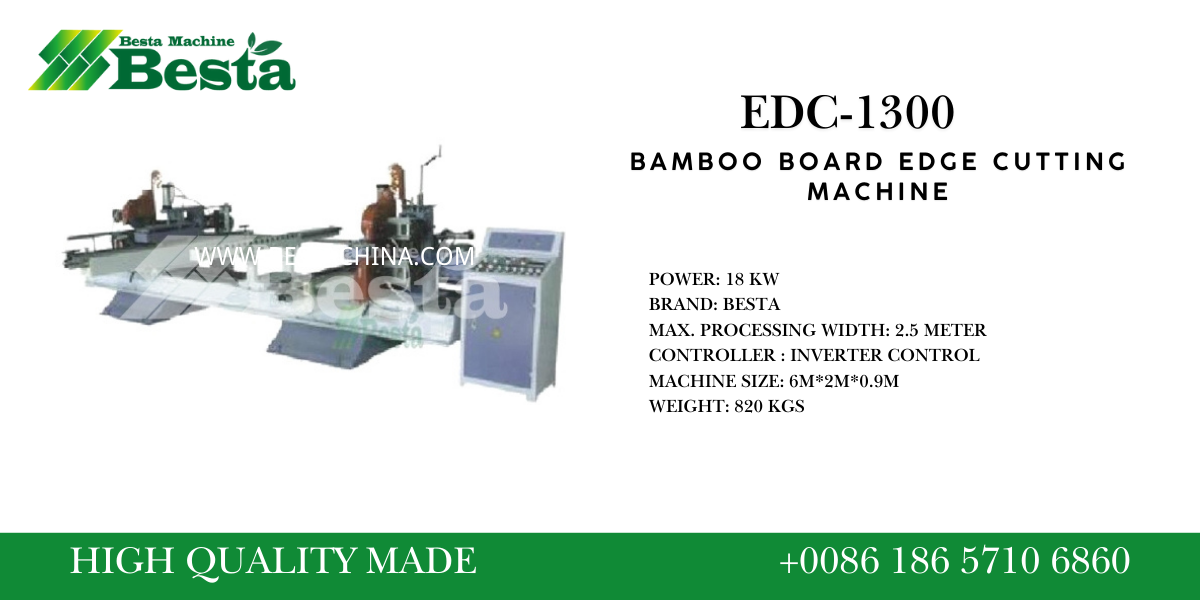

| EDC-1300 BAMBOO BOARD EDGE CUTTING MACHINE |

Power: 18 K

Max. Processing Width: 2.5 Meter

Controller : Inverter Control

Machine Size: 6M*2M*0.9M

Weight: 820 KGS

|

SERVICE

Why choose our company as your supplier?

Advantage of us

1. Our machines have the best quality all over the world. Our strand woven bamboo product lines are used by about 40 factories. The sales of Strand woven bamboo flooring which is made by our product line is about 0.2 billion every year. Our newest product line can work normally without repairfor more than one year.

2. Our processes and technology are the best. We are the firstmen who make the strand woven bamboo and develop the market. We have set up 40 factories in different area in china and foreign countries. We try to make thestrand woven bamboo using different kinds of bamboo and in different area. So we have rich experience. The strand woven bamboo products which made by ourproduction line and technology can meet industry standards and exportstandards. We also join in make the industry standards of bamboo processingequipments.

3.We provide excellent service to all our customers. We provide the machines, the detail plan of the Strand woven bamboo flooring product line. (Including machines list, factorydesign, machines layout drawing and all the things you should prepare),processes and technology, training and good after selling service. You don’t need to worry anything.

We are the best machine supplier for the people who start the making of strand woven factory at the first time.

| +0086 186 5710 6860 | |

| angel@bestachina.com、info@bestachina.com | |

| WEBSITE | www.bestachina.com 、www.bestamachine.com |

One-stop Service

|

NO.

|

NAME

|

QUANTITY

|

|

1

|

RAW BAMBOO SAWING MACHINE

(ZG-1)

|

2 SETS

|

|

2

|

BAMBOO SPLITTING MACHINE

(ZP-2500)

|

2 SETS

|

|

3

|

BAMBOO STRIP ELEMENTARY PLANING MACHINE

(MBXD-10)

|

4 SETS

|

|

4

|

HIGH SPEED FURTHER STRIP PLANING MACHINE (MBHB-4)

|

4 SETS

|

|

5

|

CARBONIZING BOILER

|

1 to 2 SETS

|

|

6

|

GLUE COATING MACHINE

|

2 SETS

|

|

7

|

DRYING ROOM FOR STRIP DRYING

|

6 SETS

|

|

8

|

BAMBOO BOARD HOT PRESSING MACHINE (YD750)

|

1 SET

|

|

9

|

BOARD EDGE CUTTING MACHINE

|

1 SET

|

|

10

|

BAMBOO BOARD SANDING MACHINE

|

1 SET

|

|

11

|

STEAM BOILER,PIPES ETC

(You can prepare locally)

|

1 SET

|

- Previous:BDK-75B 75MM Wooden Ice Spoon Bundling Machine

- Next:Bamboo BBQ Stick Making Machine (Whole Line) besta

Home

Home