- Model:

- BTM-001

Bamboo Toothpick Making Production Line (Video)

Video Link: https://www.youtube.com/watch?v=InJzKs29FxY

Bamboo Toothpick Making Production Line

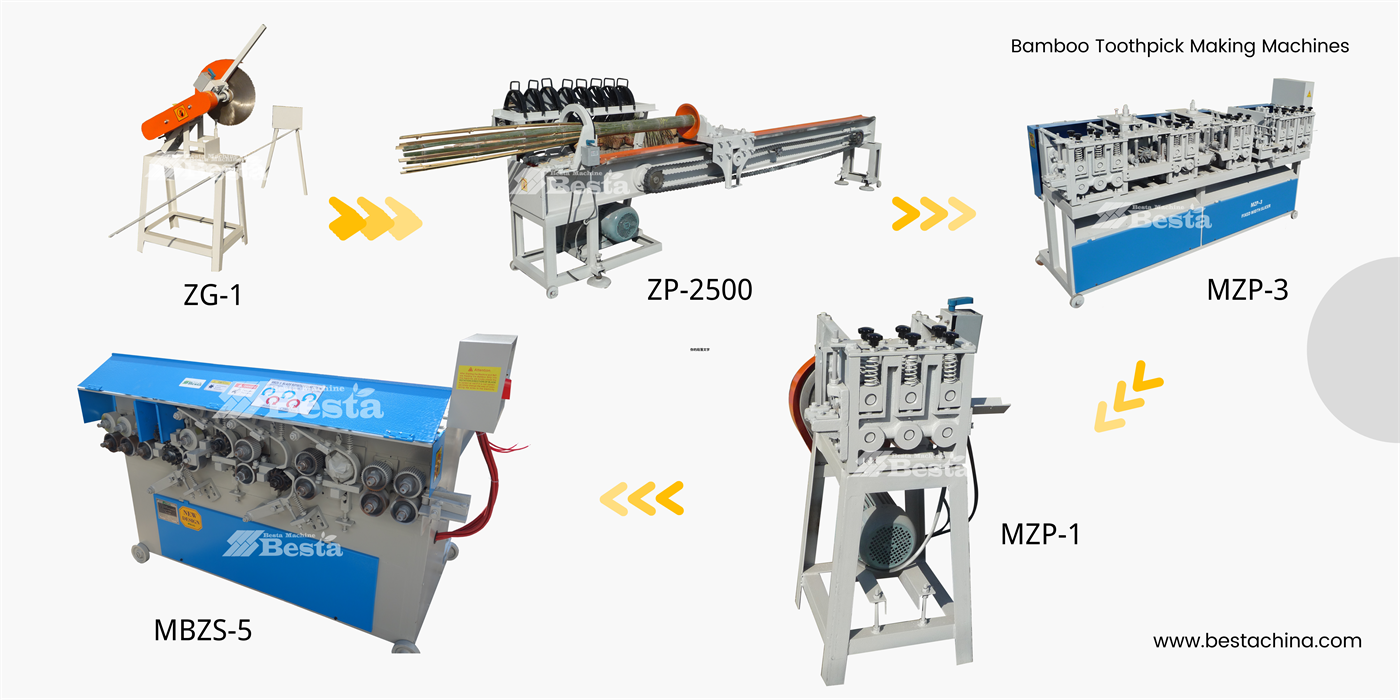

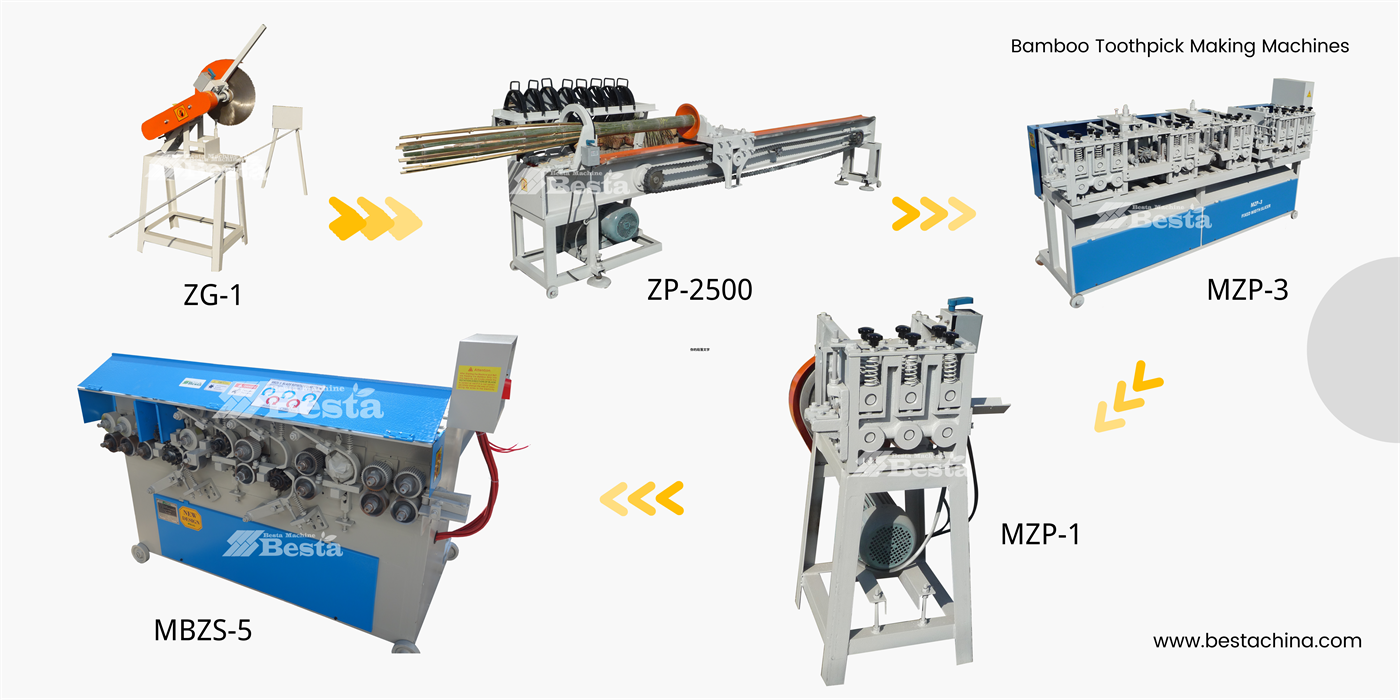

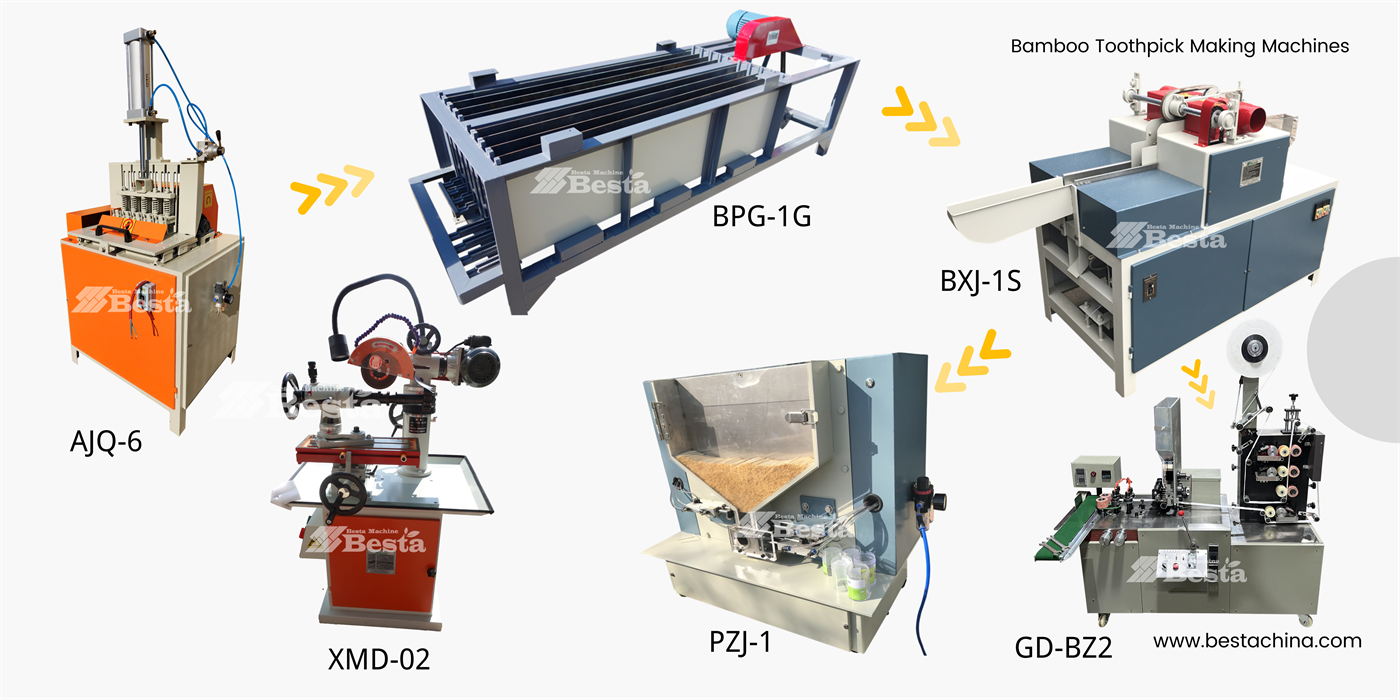

For Bamboo Toothpick Making Production Line, it is consisted by the following machines,

(KEY MACHINES) Brand: BESTA

(1) ZG-1 Raw Bamboo Sawing Machine

(2) ZP-2500 Bamboo Splitting Machine

(3) MZP-3 Fixed Width Slicer

(4) MZP-1 Small Layering Machine

(5) MBZS-5 Bamboo Wool Slicer (stick making) 2.0mm

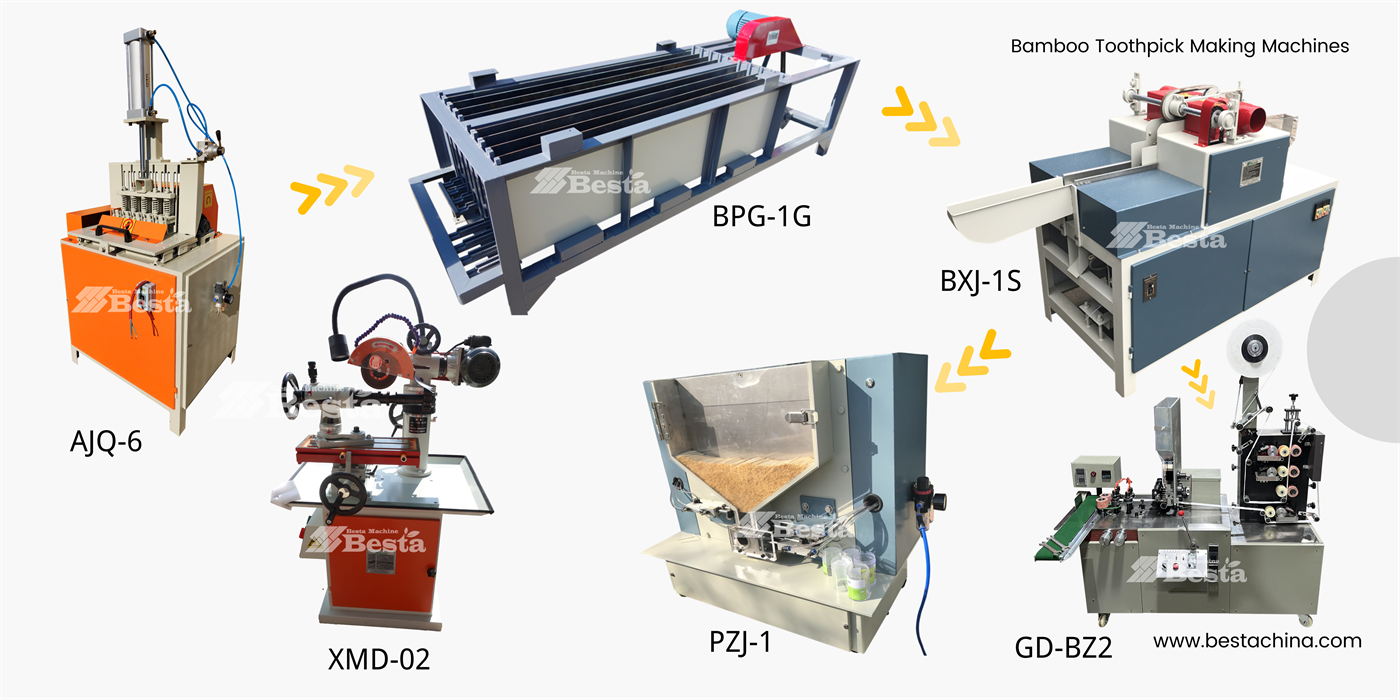

(6) BJQ-6 Precise Cutting Machine (toothpick length setting)

(7) BPG-1G High speed toothpick polishing machine

(8) BXJ-1S Toothpick Sharpening Machine (high speed type)

(9) XMD-02 Medium type blade sharpening machine

Auxiliary Equipment

(10) RFL-70 Hot Air Stove (heat supply) 1 SET

(11) SST-200 Stainless steel boiling tank 2 SETS

(12) Bricks for stove making 1 SET

(13) EH-3T Electric Hoist 1 SET

Packing Machine Option

1. Toothpick Packing Machine (1 PC Per Bag)

2. Toothpick Plastic Container Packing Machine ( by plastic container)

FREQUENTLY ASKED QUESTIONS

1. What is this production line daily output ?

Reply: The output for this production line is related to the machine quantity you purchase. If you purchase each machine 1 set,

the output is about 1.2 million pieces of double pointed toothpick per day.

2. What is the production line cost ?

Reply: For detailed machine catalog and pricelist ,welcome to email us. info@bestachina.com angel@bestachina.com

Whatsapp: 0086 186 5710 6860

3. How long does it take to produce the machines ?

Reply: The regular production time is within 30 days after confirming the receipt of advance payment.

4. What is is the payment terms ?

Reply: T/T in advance. We need to receive 30% or 50% advance payment before start production.

5. What is is the warranty range of your machine ?

Reply: Our machine are using high quality parts. For easily damaged parts like blades, rubber rollers, saws, we kindly suggest you

to buy some for future use. The machine itself service life is long. You also need to change easily damaged parts regularly.

6. Can we produce both single-pointed toothpick or double pointed toothpick by this production line ?

Reply: Yes. If you wish to produce both types, we kindly suggest you to buy 2 sets of BXJ-1S Toothpick sharpening machine

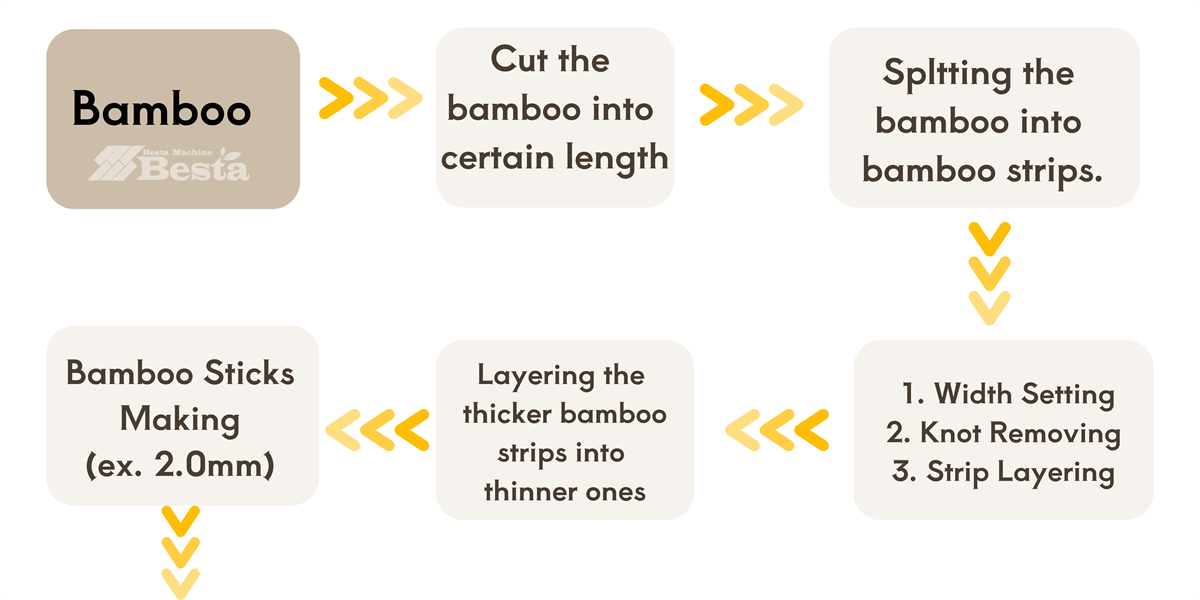

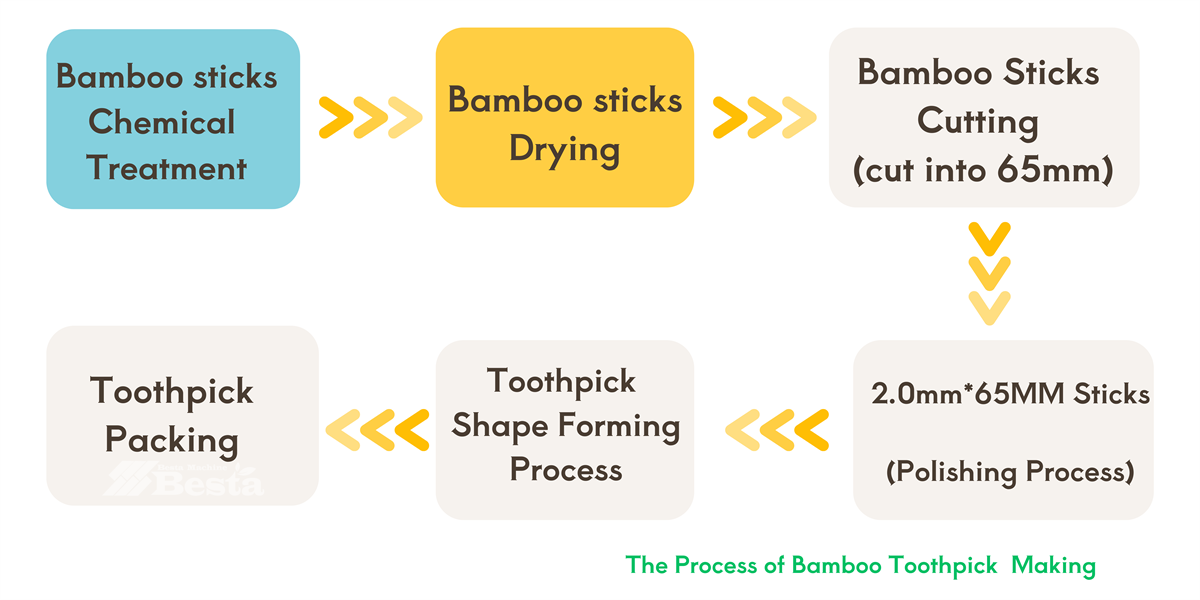

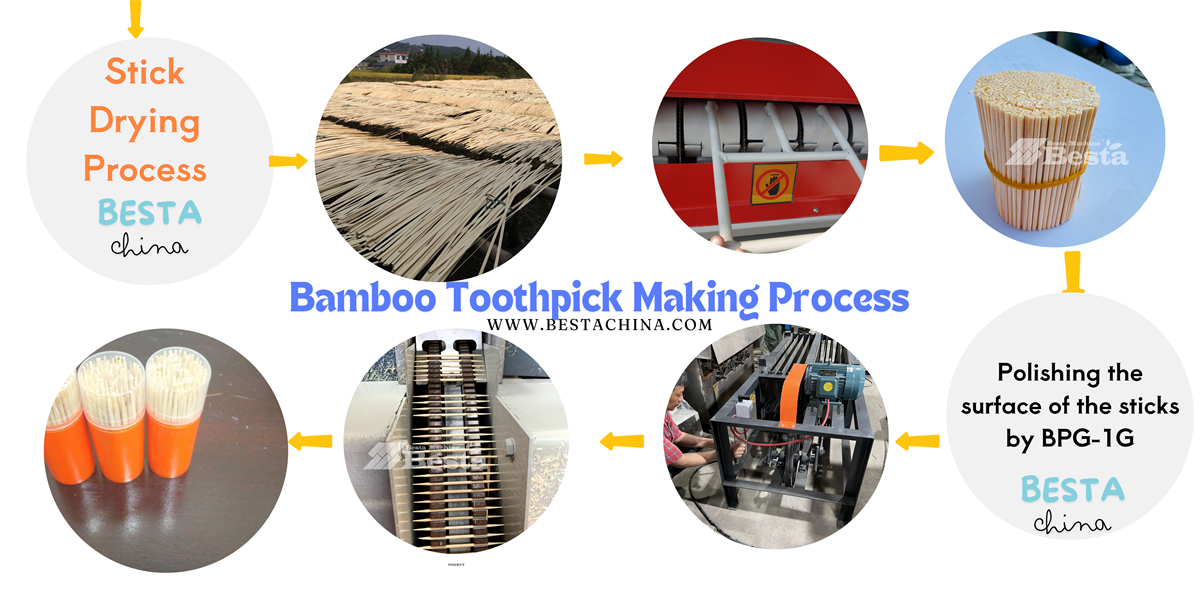

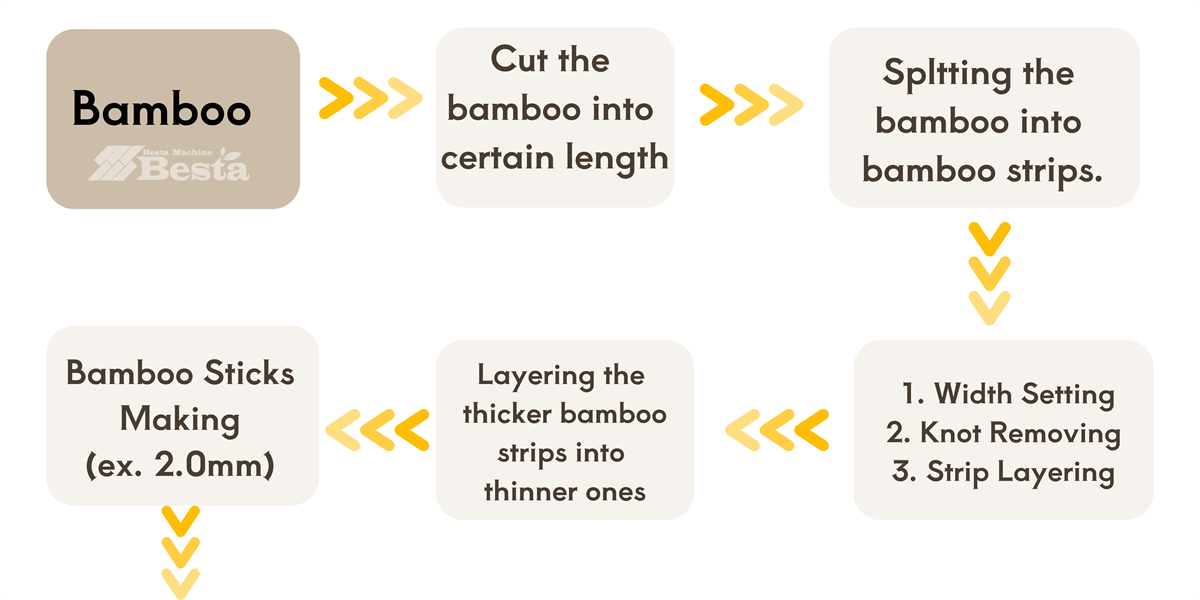

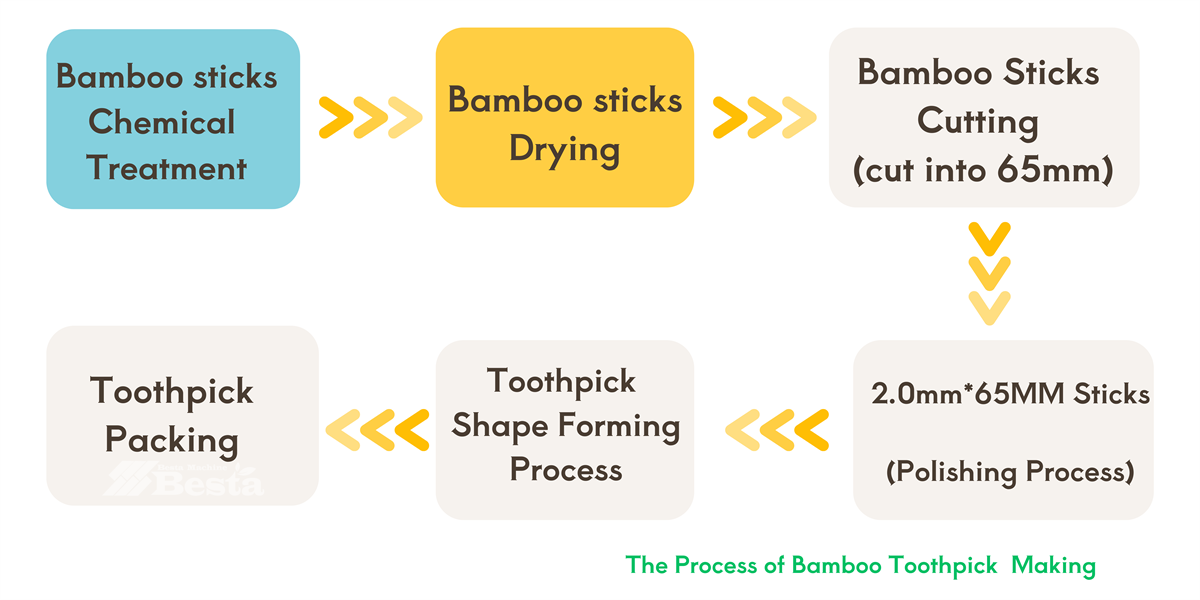

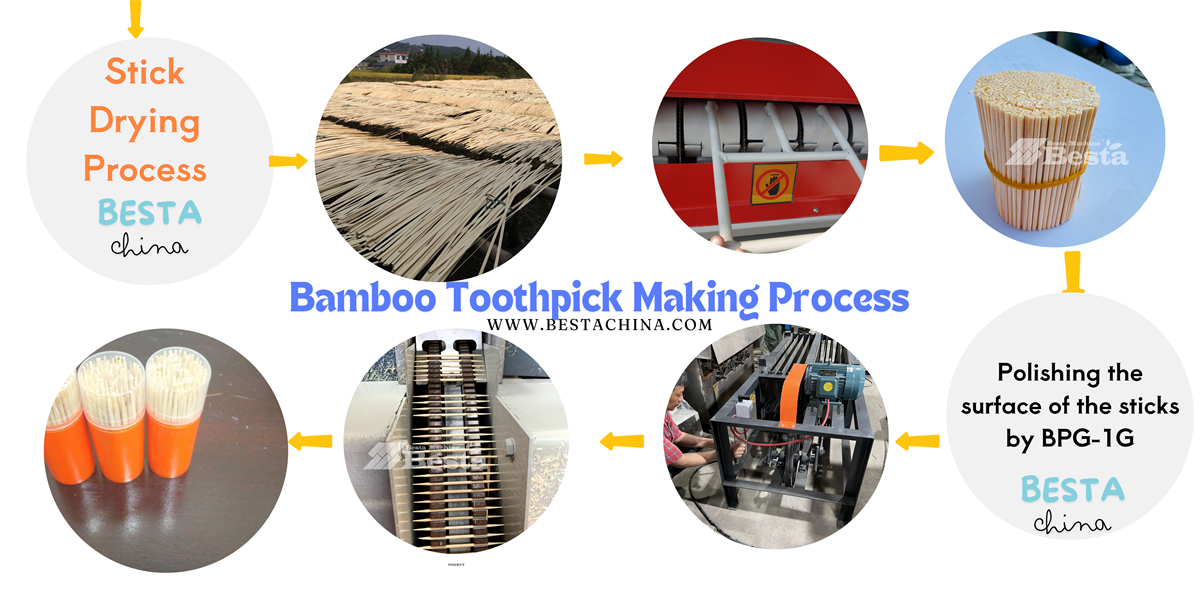

The following are the manufacturing process of bamboo toothpick,

From the process of making bamboo into bamboo toothpick, you may find that it each machine has each machines functions.

The output for this production line will be related to machine quantities, especially the quantity of toothpick sharpening machine .

Each machine output is also not same, in order to make good use of the machine output, we kindly suggest the machine quantity as follows,

| Item No. | Machine Name | Quantity Suggested |

| 1 | Bamboo Sawing Machine | 1 SET |

| 2 | Bamboo Splitting Machine | 1 SET |

| 3 | Fixed Width Slicer | 2 SETS |

| 4 | Small Layering Machine | 2 SETS |

| 5 | Bamboo Stick Shape Forming Machine | 2 SETS to 4 SETS |

| 6 | Toothpick Precise Cutting Machine | 2 SETS |

| 7 | Toothpick Polishing Machine | 1 to 2 SETS |

| 8 | Toothpick Sharpening Machine | 2 SETS |

| 9 | Toothpick Packing Machines | 2 SETS TO 4 SETS |

When you wish to order this production line, please kindly let us know which packing type you want.

If you wish to order 1 set of toothpick sharpening machine, the output for shape forming double pointed toothpick, it is 2500 PCS/MIN*60MINS*8 HOURS=

1,200,000 PCS. For new starters who first time set up this project, you can also considering each machine 1 set. It is also fine.

Our machines are widely exported to Nigeria, Tanzania, Ghana, Brazil, India, Indonesia and other countries. We will

test each machine into good performance before machine delivery and take detailed record photos and videos.

We have more than 25 years history in bamboo processing machine industries and gained reach experiences. We also

have established our own import and export company for handling our machine export named: Hangzhou Hengying

Import and Export Co., Ltd. The followings are the packing photos of our machines.

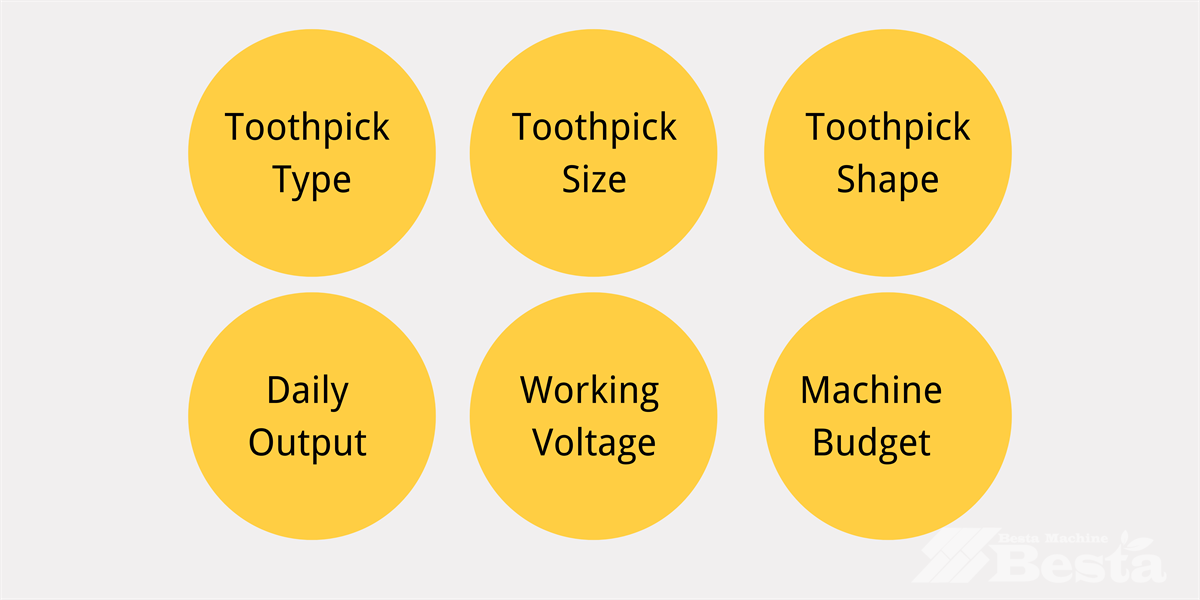

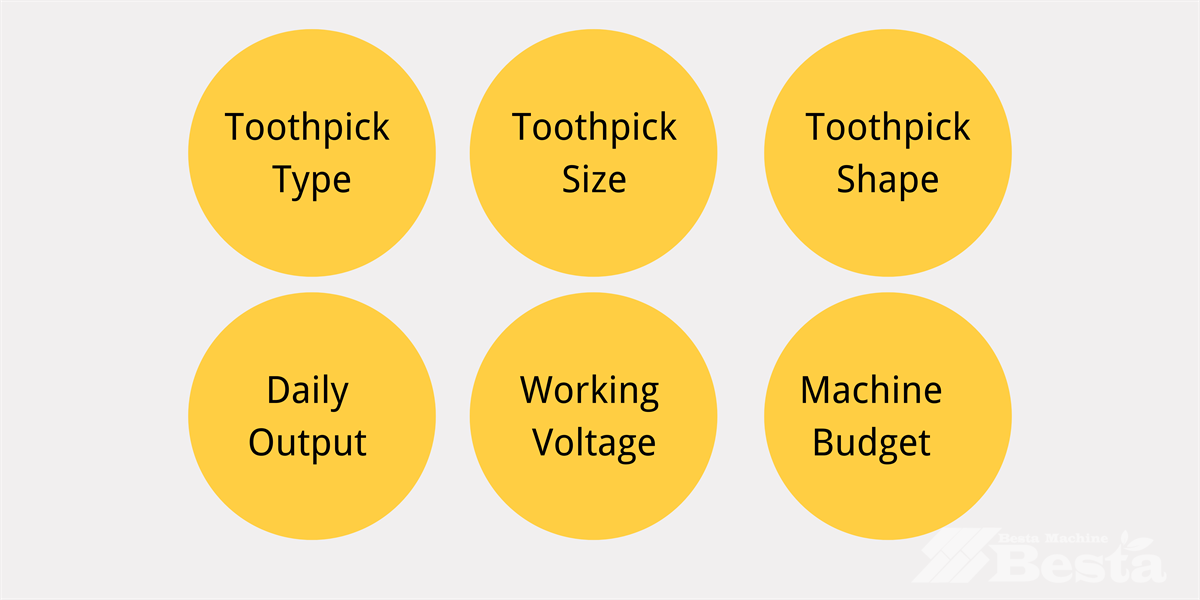

Before you wish to start this project, please kindly let us know

1) You wish to make bamboo toothpick or wooden toothpick ? Both product line we can provide. The main difference the the raw materials differene.

2) What is your daily output requirement ? for example 1.2million PCS/day, 2.4 million PCS/day etc.

3) Do you wish to produce double-pointed toothpick or single pointed toothpick?

4) What is your rough machine budget range in USD (MAX. range). so that we will try to give you suggestion within your

budget and make this project more practical.

5) What is your local working voltage (three phases).

What are other machines needed for starting this project ?

Except the key machines for bamboo processing, making bamboo into toothpick, you also need the following machine

| 1 | Stainless Steel Boiling Tank-It is for stick boiling purpose. |

| 2 | Electric Hoist -It is for bamboo sticks lifting |

| 3 | Hot Air Stove.--It is for bamboo stick drying purpose |

| 4 | Steam Boiler (optional) . |

After using MBZS-5 Bamboo Stick shape forming machine, you will get fresh bamboo sticks. This fresh sticks need to do

stick boiling process. This process is also called stick treatment. It is for removing the sugar, insects from the sticks. After

stick boiling, you need to the drying process of the sticks, making the boiled fresh sticks into dried ones. The moisture rate

for the sticks should be control below 10%. The sticks cutting process, polishing process and sharpening process, it is started

from dried sticks. (Please noted).

When you buy the machines, we also wish you can buy some spare parts for future use. It is very necessary. For some parts, it need regular maintenance and also replacement when it is reaching its service life. For examples, saws, feeding rollers, shaping blade, flat blades, grinding wheels, saws for cutting ,Iron Feeding roller, rubber feeding roller, flat planing blade etc. We will give you very detailed suggestion when you confirm the final quantity of the machines.

How to buy the machine from our company ?

Welcome to contact us by email or by whatsapp. We will send you detailed project proposal regarding this project. Do not hesitate to let us know your requirements. We will offer you machine suggestion. After you decided to start this production line and confirming machine quantity, name, size of the product, working voltage, destination port, send us consignee information, we will make formal proforma invoice for you.

If you have any question in this project set up, do not hestiate to let us know. Welcom to whatsapp us or email us.

Bamboo Toothpick Making Production Line (Video)

Video Link: https://www.youtube.com/watch?v=InJzKs29FxY

Bamboo Toothpick Making Production Line

For Bamboo Toothpick Making Production Line, it is consisted by the following machines,

(KEY MACHINES) Brand: BESTA

(1) ZG-1 Raw Bamboo Sawing Machine

(2) ZP-2500 Bamboo Splitting Machine

(3) MZP-3 Fixed Width Slicer

(4) MZP-1 Small Layering Machine

(5) MBZS-5 Bamboo Wool Slicer (stick making) 2.0mm

(6) BJQ-6 Precise Cutting Machine (toothpick length setting)

(7) BPG-1G High speed toothpick polishing machine

(8) BXJ-1S Toothpick Sharpening Machine (high speed type)

(9) XMD-02 Medium type blade sharpening machine

Auxiliary Equipment

(10) RFL-70 Hot Air Stove (heat supply) 1 SET

(11) SST-200 Stainless steel boiling tank 2 SETS

(12) Bricks for stove making 1 SET

(13) EH-3T Electric Hoist 1 SET

Packing Machine Option

1. Toothpick Packing Machine (1 PC Per Bag)

2. Toothpick Plastic Container Packing Machine ( by plastic container)

FREQUENTLY ASKED QUESTIONS

1. What is this production line daily output ?

Reply: The output for this production line is related to the machine quantity you purchase. If you purchase each machine 1 set,

the output is about 1.2 million pieces of double pointed toothpick per day.

2. What is the production line cost ?

Reply: For detailed machine catalog and pricelist ,welcome to email us. info@bestachina.com angel@bestachina.com

Whatsapp: 0086 186 5710 6860

3. How long does it take to produce the machines ?

Reply: The regular production time is within 30 days after confirming the receipt of advance payment.

4. What is is the payment terms ?

Reply: T/T in advance. We need to receive 30% or 50% advance payment before start production.

5. What is is the warranty range of your machine ?

Reply: Our machine are using high quality parts. For easily damaged parts like blades, rubber rollers, saws, we kindly suggest you

to buy some for future use. The machine itself service life is long. You also need to change easily damaged parts regularly.

6. Can we produce both single-pointed toothpick or double pointed toothpick by this production line ?

Reply: Yes. If you wish to produce both types, we kindly suggest you to buy 2 sets of BXJ-1S Toothpick sharpening machine

The following are the manufacturing process of bamboo toothpick,

From the process of making bamboo into bamboo toothpick, you may find that it each machine has each machines functions.

The output for this production line will be related to machine quantities, especially the quantity of toothpick sharpening machine .

Each machine output is also not same, in order to make good use of the machine output, we kindly suggest the machine quantity as follows,

| Item No. | Machine Name | Quantity Suggested |

| 1 | Bamboo Sawing Machine | 1 SET |

| 2 | Bamboo Splitting Machine | 1 SET |

| 3 | Fixed Width Slicer | 2 SETS |

| 4 | Small Layering Machine | 2 SETS |

| 5 | Bamboo Stick Shape Forming Machine | 2 SETS to 4 SETS |

| 6 | Toothpick Precise Cutting Machine | 2 SETS |

| 7 | Toothpick Polishing Machine | 1 to 2 SETS |

| 8 | Toothpick Sharpening Machine | 2 SETS |

| 9 | Toothpick Packing Machines | 2 SETS TO 4 SETS |

When you wish to order this production line, please kindly let us know which packing type you want.

If you wish to order 1 set of toothpick sharpening machine, the output for shape forming double pointed toothpick, it is 2500 PCS/MIN*60MINS*8 HOURS=

1,200,000 PCS. For new starters who first time set up this project, you can also considering each machine 1 set. It is also fine.

Our machines are widely exported to Nigeria, Tanzania, Ghana, Brazil, India, Indonesia and other countries. We will

test each machine into good performance before machine delivery and take detailed record photos and videos.

We have more than 25 years history in bamboo processing machine industries and gained reach experiences. We also

have established our own import and export company for handling our machine export named: Hangzhou Hengying

Import and Export Co., Ltd. The followings are the packing photos of our machines.

Before you wish to start this project, please kindly let us know

1) You wish to make bamboo toothpick or wooden toothpick ? Both product line we can provide. The main difference the the raw materials differene.

2) What is your daily output requirement ? for example 1.2million PCS/day, 2.4 million PCS/day etc.

3) Do you wish to produce double-pointed toothpick or single pointed toothpick?

4) What is your rough machine budget range in USD (MAX. range). so that we will try to give you suggestion within your

budget and make this project more practical.

5) What is your local working voltage (three phases).

What are other machines needed for starting this project ?

Except the key machines for bamboo processing, making bamboo into toothpick, you also need the following machine

| 1 | Stainless Steel Boiling Tank-It is for stick boiling purpose. |

| 2 | Electric Hoist -It is for bamboo sticks lifting |

| 3 | Hot Air Stove.--It is for bamboo stick drying purpose |

| 4 | Steam Boiler (optional) . |

After using MBZS-5 Bamboo Stick shape forming machine, you will get fresh bamboo sticks. This fresh sticks need to do

stick boiling process. This process is also called stick treatment. It is for removing the sugar, insects from the sticks. After

stick boiling, you need to the drying process of the sticks, making the boiled fresh sticks into dried ones. The moisture rate

for the sticks should be control below 10%. The sticks cutting process, polishing process and sharpening process, it is started

from dried sticks. (Please noted).

When you buy the machines, we also wish you can buy some spare parts for future use. It is very necessary. For some parts, it need regular maintenance and also replacement when it is reaching its service life. For examples, saws, feeding rollers, shaping blade, flat blades, grinding wheels, saws for cutting ,Iron Feeding roller, rubber feeding roller, flat planing blade etc. We will give you very detailed suggestion when you confirm the final quantity of the machines.

How to buy the machine from our company ?

Welcome to contact us by email or by whatsapp. We will send you detailed project proposal regarding this project. Do not hesitate to let us know your requirements. We will offer you machine suggestion. After you decided to start this production line and confirming machine quantity, name, size of the product, working voltage, destination port, send us consignee information, we will make formal proforma invoice for you.

If you have any question in this project set up, do not hestiate to let us know. Welcom to whatsapp us or email us.

Home

Home