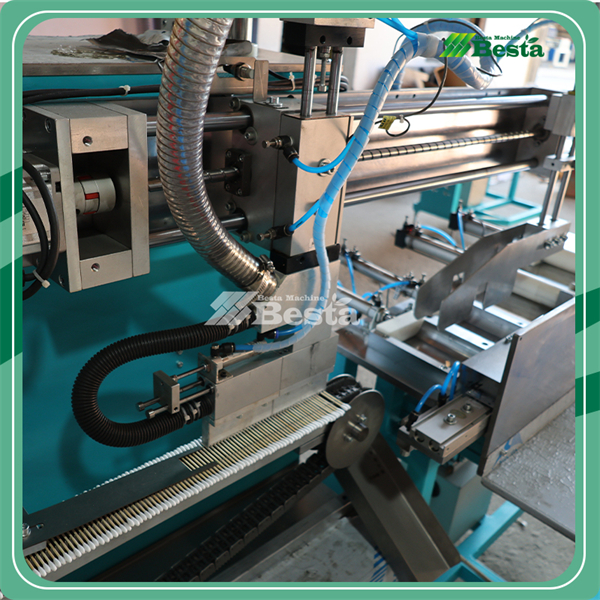

Automatic Cotton Bud Making Machine

MODEL: CB-1000

FULLY AUTOMATIC COTTON BUD MAKING MACHINE

Output: 800-1000/min

Power: 10KW Voltage: 380V

Weight: 1200KG

Overall dimensions: 9.5 meters long × 1 meter wide × 1.6 meters high (9500*1000*1600MM)

(using 3-8g cotton sliver)

The warm air drying type fully automatic cotton swab packaging machine is controlled by PLC program and uses closed cycle hot air drying technology to dry the water during operation, and then the vacuum suction manipulator automatic packaging equipment controlled by screw servo motor drive completes the packaging. Each link realizes a one-stop process from gluing, shredding cotton, forming, drying, and packaging.

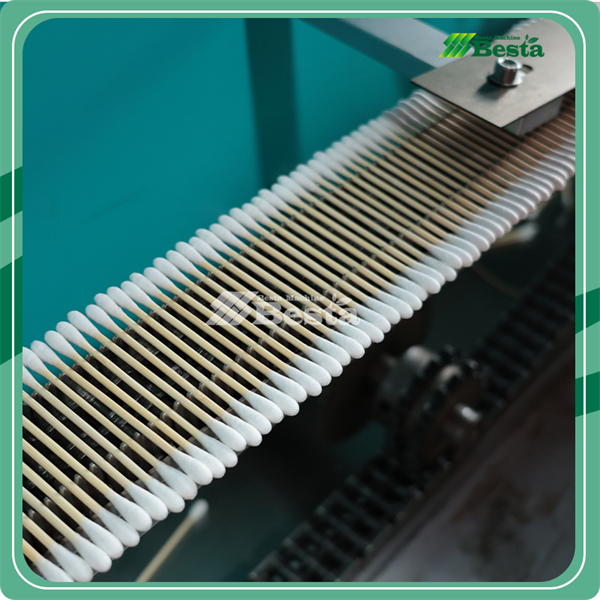

For the first time, the machine head uses shredded cotton swabs, which can use 3-6 grams of cotton slivers. It is suitable for the production of daily and medical cotton swabs. Depending on the size of the cotton swab head, it can be used for the production of extremely small baby cotton swabs and large-head gynecological cotton swabs. Restricted by the size and weight of the cotton sliver, cotton swabs of different lengths can be produced

by changing the width of the suction port. This machine is universal and can be used to produce medical cotton swabs when connected to a conveyor belt and separation table or automatic bagging, and is equipped with a robot. The suction stick and packaging table can also produce daily-use cotton swabs, saving customers the cost of cotton swabs. The flat-plate broken cotton swab machine is easier to operate and maintain than the traditional disc machine. It does not need to replace the rubber and frequently adjust the mold. It has a hook chain. This prevents the machine from being clogged due to raw materials. The mold is equipped with a flat plate standard. Because it has an upper cover, the cotton swabs produced are of the same size, and there are no uneven cotton swabs.

The machine uses a two-stage hot air circulation drying box, which automatically blows out and inhales the hot air in the drying box through a medium-pressure fan, saving electricity. The power is 6KW, which can ensure that the humidity of the dry bath of cotton swabs is 5% and will not become moldy. The workshop also The temperature will not be very high due to the oven. The door panels of all machines are made of 304 stainless steel, making the equipment more high-end.

The machine uses a hanging touch screen, which makes it very convenient to set parameters. The packaging table can be made into round cans, ziplock bags, square boxes and other packaging forms according to product needs. One machine can be equipped with a variety of packaging tables, which is also easy to replace. This machine requires One start-up person and one packaging person. If there are different types of packaging tables, the cost will be additional.

ELECTRONIC PARTS BRAND

Taiwan Weilun touch screen Japan Mitsubishi PLC Delta servo motor Delta inverter Airtac cylinder Electric motor Centrifugal fan Digital display peristaltic glue pump Schneider low-voltage electrical appliances Omron electronic sensing components

FREE SPARE PARTS WITH MACHINE

Air regulating valve, metal sensor, open-thread heating pipe, material box brush, glue pump water pipe, main machine belt rubbing, Allen wrench, tool box

This machine is suitable for packaging plastic ziplock bags, plastic cylinders, plastic square boxes, etc.

1. Adopt digital display peristaltic pump glue supply system, digital fine-tuning is precise and easy to control the amount of glue.

2. Double-layer closed drying system with automatic hot air circulation function controls the dryness of cotton swabs at 6%.

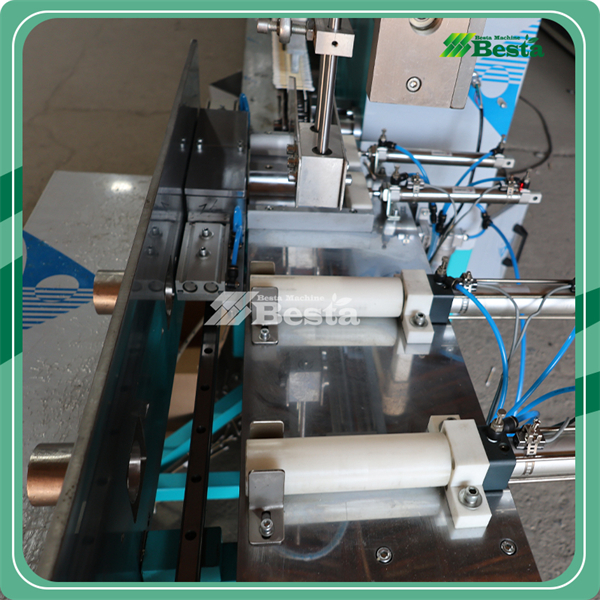

3. The servo motor screw-type tracking suction rod makes the robot suction rod more stable and easy to adjust and operate.

4. Automatic positioning function for cotton swab mold assembly and disassembly, no need for debugging.

5. The hanging touch screen makes operation more convenient, and the external door panels of the machine are made of 304 stainless steel.

6. Using 304 stainless steel forming mold and Japanese-made thickened rubbing tape to make the cotton swab more beautiful and durable.

7. When the host speed changes, the computer automatically calculates it, and the suction rod can automatically track it without adjustment.

Automatic Cotton Bud Making Machine

MODEL: CB-1000

FULLY AUTOMATIC COTTON BUD MAKING MACHINE

Output: 800-1000/min

Power: 10KW Voltage: 380V

Weight: 1200KG

Overall dimensions: 9.5 meters long × 1 meter wide × 1.6 meters high (9500*1000*1600MM)

(using 3-8g cotton sliver)

The warm air drying type fully automatic cotton swab packaging machine is controlled by PLC program and uses closed cycle hot air drying technology to dry the water during operation, and then the vacuum suction manipulator automatic packaging equipment controlled by screw servo motor drive completes the packaging. Each link realizes a one-stop process from gluing, shredding cotton, forming, drying, and packaging.

For the first time, the machine head uses shredded cotton swabs, which can use 3-6 grams of cotton slivers. It is suitable for the production of daily and medical cotton swabs. Depending on the size of the cotton swab head, it can be used for the production of extremely small baby cotton swabs and large-head gynecological cotton swabs. Restricted by the size and weight of the cotton sliver, cotton swabs of different lengths can be produced

by changing the width of the suction port. This machine is universal and can be used to produce medical cotton swabs when connected to a conveyor belt and separation table or automatic bagging, and is equipped with a robot. The suction stick and packaging table can also produce daily-use cotton swabs, saving customers the cost of cotton swabs. The flat-plate broken cotton swab machine is easier to operate and maintain than the traditional disc machine. It does not need to replace the rubber and frequently adjust the mold. It has a hook chain. This prevents the machine from being clogged due to raw materials. The mold is equipped with a flat plate standard. Because it has an upper cover, the cotton swabs produced are of the same size, and there are no uneven cotton swabs.

The machine uses a two-stage hot air circulation drying box, which automatically blows out and inhales the hot air in the drying box through a medium-pressure fan, saving electricity. The power is 6KW, which can ensure that the humidity of the dry bath of cotton swabs is 5% and will not become moldy. The workshop also The temperature will not be very high due to the oven. The door panels of all machines are made of 304 stainless steel, making the equipment more high-end.

The machine uses a hanging touch screen, which makes it very convenient to set parameters. The packaging table can be made into round cans, ziplock bags, square boxes and other packaging forms according to product needs. One machine can be equipped with a variety of packaging tables, which is also easy to replace. This machine requires One start-up person and one packaging person. If there are different types of packaging tables, the cost will be additional.

ELECTRONIC PARTS BRAND

Taiwan Weilun touch screen Japan Mitsubishi PLC Delta servo motor Delta inverter Airtac cylinder Electric motor Centrifugal fan Digital display peristaltic glue pump Schneider low-voltage electrical appliances Omron electronic sensing components

FREE SPARE PARTS WITH MACHINE

Air regulating valve, metal sensor, open-thread heating pipe, material box brush, glue pump water pipe, main machine belt rubbing, Allen wrench, tool box

This machine is suitable for packaging plastic ziplock bags, plastic cylinders, plastic square boxes, etc.

1. Adopt digital display peristaltic pump glue supply system, digital fine-tuning is precise and easy to control the amount of glue.

2. Double-layer closed drying system with automatic hot air circulation function controls the dryness of cotton swabs at 6%.

3. The servo motor screw-type tracking suction rod makes the robot suction rod more stable and easy to adjust and operate.

4. Automatic positioning function for cotton swab mold assembly and disassembly, no need for debugging.

5. The hanging touch screen makes operation more convenient, and the external door panels of the machine are made of 304 stainless steel.

6. Using 304 stainless steel forming mold and Japanese-made thickened rubbing tape to make the cotton swab more beautiful and durable.

7. When the host speed changes, the computer automatically calculates it, and the suction rod can automatically track it without adjustment.

Home

Home