Strand Woven Bamboo Board Furniture Board Line

| MODEL | NAME | QTY. |

| ZG-1 | Bamboo Sawing Machine | 5 |

| ZP-2500 | Bamboo Splitting Machine | 4 |

| MZP-3 | Fixed Width Slicer (knot removing etc) | 10 |

| MZP-3L | Strip Slicing Machine (For thick bamboo) | 5 |

| MZP-1 | Small Layering Machine | 10 |

| MZKP-N1 | Bamboo Expanding and Stranding Machine | 2 |

| TZQ-020 | Medium type blade sharpening machine | 2 |

| AB-YS-4 | Strip Stranding Machine (fiber breaking) | 20 |

| YDCB-6M | Carbonizing Boiler | 4 |

| YDDR-55N | Drying Machine | 4 |

| YD12-3600 | Cold Press (3600T) for strand woven beam | 1 |

| YDMC-2500 | Mould Cavity | 1 |

| YDLO-2500 | Loading Machine | 1 |

| YDUL-2500 | Unloading Machine | 1 |

| YDMO-2500 | Mould (2500*140*143mm) | 500 |

| YDCU-2500 | Curing Machine | 1 |

| YDCO-2500 | Cooling Machine | 1 |

| YDDE-2500 | Demolding Machine | 1 |

| YDEC-2500 | End Cutting Machine | 1 |

| YDTM-2500 | Trimming Machine | 1 |

| YDFS-2500 | Frame Sawing Machine | 2 |

| YDBRM-2500 | Balance Room | 8 |

| GDM-2500 | Glue Dipping Machine | 4 |

| GB-2500 | Glue Dipping Baskets | 16 |

| GMM-2500 | Glue Making Machine | 1 |

| YDGRM-01 | Grinding Machine (Type 1) | 2 |

| YDGRM-02 | Grinding Machine (Type 2) | 1 |

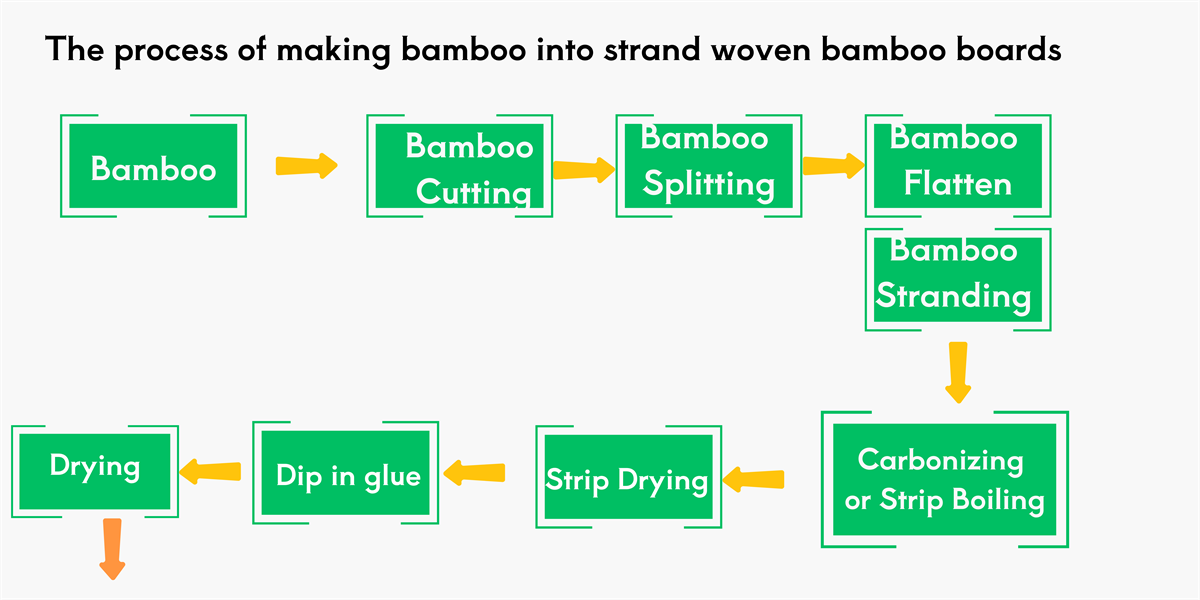

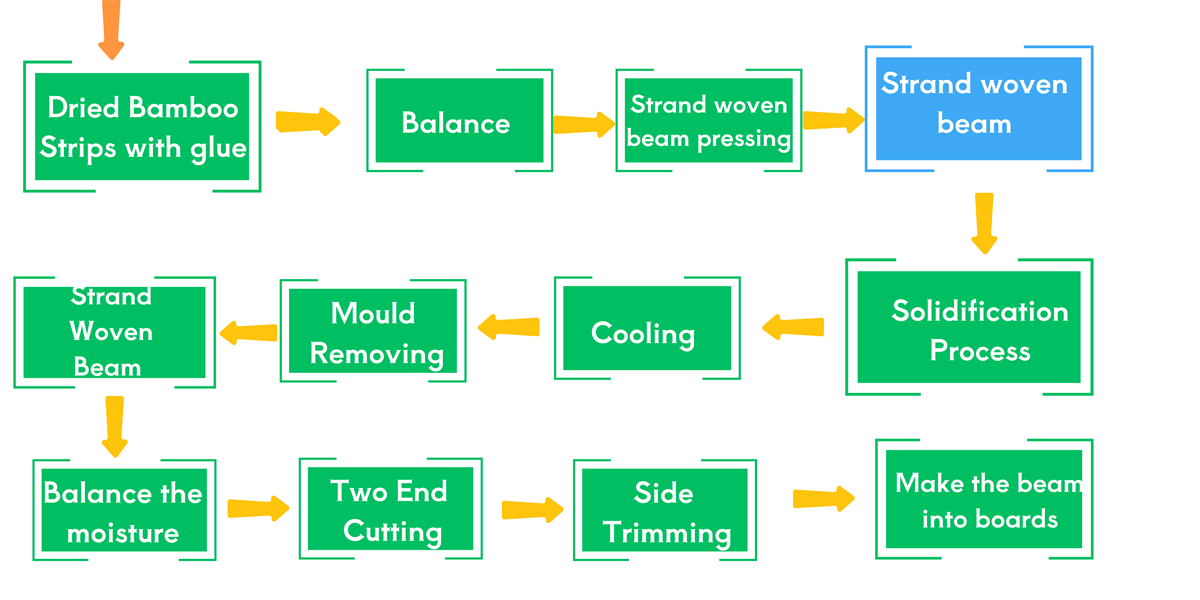

The process of making bamboo into bamboo boards

SERVICE

Why choose our company as your supplier?

Advantage of us

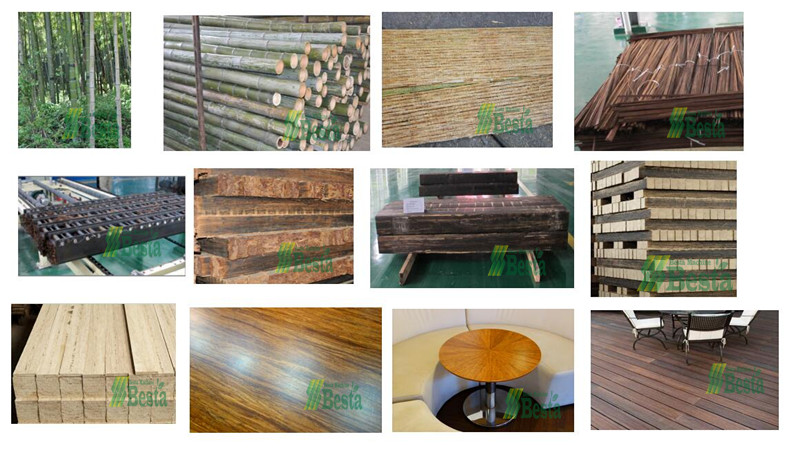

1. Our machines have the best quality all over the world. Our strand woven bamboo product lines are used by about 40 factories. The sales of Strand woven bamboo flooring which is made by our product line is about 0.2 billion every year. Our newest product line can work normally without repairfor more than one year.

2. Our processes and technology are the best. We are the firstmen who make the strand woven bamboo and develop the market. We have set up 40 factories in different area in china and foreign countries. We try to make thestrand woven bamboo using different kinds of bamboo and in different area. So we have rich experience. The strand woven bamboo products which made by ourproduction line and technology can meet industry standards and exportstandards. We also join in make the industry standards of bamboo processingequipments.

3.We provide excellent service to all our customers. We provide the machines, the detail plan of the Strand woven bamboo flooring product line. (Including machines list, factorydesign, machines layout drawing and all the things you should prepare),processes and technology, training and good after selling service. You don’t need to worry anything.

We are the best machine supplier for the people who start the making of strand woven factory at the first time.

| +0086 186 5710 6860 | |

| angel@bestachina.com、info@bestachina.com | |

| WEBSITE | www.bestachina.com 、www.bestamachine.com |

Professional strand woven bamboo flooring machine supplier

--Besta Bamboo Machine Co., Limited. (CHINA)

Key Machines

Key Machines

Glue Dipping Machine

Bamboo Strip Drying Machine (2 sets)

Stand Woven beam/block Press (complete set)

(making glued dried strip into bamboo blocks. etc. (2500*140*143mm) It is consisted by Press body/mould cavity/ material loading machine/ unloading machine/ moulds etc)

Block Curing Machine (solidification tunnel)

Block Cooling Machine

Mould Removing Machine

End Cutting Machine

Side Trimming Machine

Multi-blade Sawing Machine (or Frame Sawing Machine. )

Sanding Machine

Balance Room

We have detailed project proposal, machine list with photos/techincal datas/all the

things related to this projects. Welcome to email us for more detailed informations.

The Process of Making Bamboo into Strand Woven Bamboo Flooring (as follows)

The Process of Making Bamboo into Strand Woven Bamboo Flooring (as follows)

1. Primary Stage (making bamboo into bamboo strands)

Bamboo Cutting/Splitting/Slicing/Stranding/

Carbonization or Stick Boiling /Drying of bamboo strips.

2. Secondary Stage of Process

Glue dipping/Drying/strand woven bamboo beam pressing (block making)/solidating process (curing)/cooling/mould removing/end cutting/side trimming/sanding/

3. Third Stage of Process: Making strand woven board into strand

woven bamboo flooring (a series of machine)

Strand Woven bamboo funiture board/Flooring Making Process

Strand Woven bamboo funiture board/Flooring Making Process

Welcome to email us directly for more detailed information.

HIGH QUALITY, EXCELLENT SERVICE

HIGH QUALITY, EXCELLENT SERVICE

1. Our BESTA brand Bamboo Processing Machine are widely exported to more than 30 countries and is the world top quality bamboo machines. We keep innovation all the times. We have rich experiences both in China and abroad Countries like India, Indonesia, African countries, South American countries, etc. We have set up factories in different area in china and foreign countries. We have made the strand woven bamboo using different kinds of bamboo and in different areas.

2. Our latest product line can work normally without repairing for more than one year. We can offer a whole package plan for our customers, including machines, technology, layout, training and services. We can make sure you can make high quality strand woven bamboo boards or strand woven bamboo floorings.

3. The strand woven bamboo products which are made by our production line and technology can meet industry standards and export standards. We have confidence to say that we are your right and professional business partner and will help you to sucess.

4. For detailed strand woven bamboo flooring project proposals, welcome to email us. For all the things you concerned, welcome to email us. Email: info@bestachina.com (Angel Zhou)

CHOOSE US, CHOOSE PROFESSIONAL ---DIRECT WAY TO SUCESS.

CONTACT US

CONTACT US

BESTA BAMBOO MACHINE CO., LIMITED.

Angel Zhou 0086 186 5710 6860

angelzhou1224@gmail.com

info@bestachina.com

Skype: angel12242008

www.bestachina.com

www.bestamachine.com

(whatsapp, LINE software )

- Previous:BDK-75B 75MM Wooden Ice Spoon Bundling Machine

- Next:MZP-3 Bamboo Strip Slicing Machine, Fixed Width Slicer,Bamboo Toothpick Making Machine

Home

Home