INTRODUCTION

Strip Drying Machine

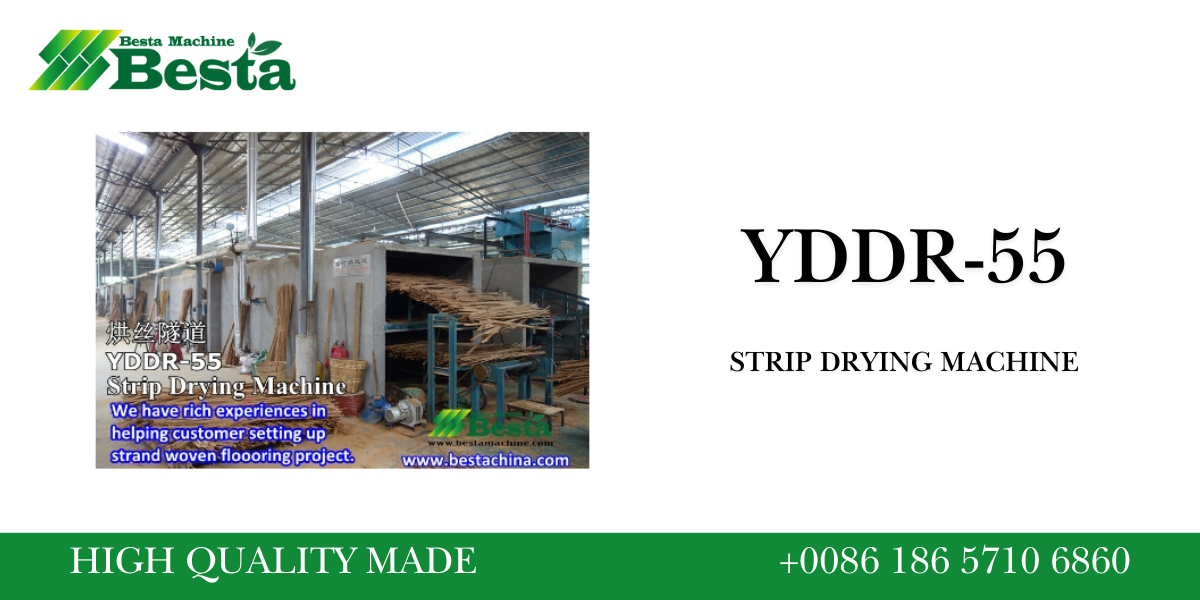

| Model | YDDR-55 |

| Name | Strip Drying Machine |

| Application | Strand Woven Flooring Making |

| Electricity Power Input | 380V,50HZ |

| Power | 27KW |

| Dimension Size | 3.2M*2.4M*60Meter |

| Speed | 0.7 Meter/Min—7Meter/Min |

| Numbers of Fans | 14 |

| Numbers of Layer | 2 Layers |

| Heating Medium | Steam or Oil |

| Output | 20 Tons Materials per 18 hours |

When you will need this drying machine?

1. After steaming of strip/After the carbonizing of bamboo strip, you need this machine to make the the strip dried.

2. After dipping the strip into glue and before presssing them into strand woven beams, you also need this machine.

For one production line, we kindly suggest you to buy 2 SETS of YDDR-55 strip drying machine.

For a better understanding about our whole production line of strand woven flooring making, welcome to email us for the product catalogue and pricelist. We will send you very detailed project proposals. Our company is the world famous bamboo processing machine supplier and for flooring making machines, our company has absolute advantages. In China, most of the top 10 big manufacturers are using our machines and we have helped more than 40 factories to set up strand woven flooring lines sucessfully. We are looking forward to cooperation with you.

SERVICE

Why choose our company as your supplier?

Advantage of us

1. Our machines have the best quality all over the world. Our strand woven bamboo product lines are used by about 40 factories. The sales of Strand woven bamboo flooring which is made by our product line is about 0.2 billion every year. Our newest product line can work normally without repairfor more than one year.

2. Our processes and technology are the best. We are the firstmen who make the strand woven bamboo and develop the market. We have set up 40 factories in different area in china and foreign countries. We try to make thestrand woven bamboo using different kinds of bamboo and in different area. So we have rich experience. The strand woven bamboo products which made by ourproduction line and technology can meet industry standards and exportstandards. We also join in make the industry standards of bamboo processingequipments.

3.We provide excellent service to all our customers. We provide the machines, the detail plan of the Strand woven bamboo flooring product line. (Including machines list, factorydesign, machines layout drawing and all the things you should prepare),processes and technology, training and good after selling service. You don’t need to worry anything.

We are the best machine supplier for the people who start the making of strand woven factory at the first time.

| +0086 186 5710 6860 | |

| angel@bestachina.com、info@bestachina.com | |

| WEBSITE | www.bestachina.com 、www.bestamachine.com |

One-stop Service

CHINA BEST BAMBOO FLOORING MACHINE SUPPLIER, STRAND WOVEN BAMBOO FLOORING MACHINE SUPPLIER.

YDDR-55 Strip Drying Machine, Bamboo Strip Drying Machine,

Bamboo Strip Drying Tunnel

Application: Strand Woven Flooring Making

Electricity Power Input: 380V,50HZ

Power: 24 KW

Dimension Size: 3.2M*2.4M*55Meter

Speed: 0.7 meter/Min---7Meter/min

Numbers of Fans: 14

Numbers of Layer: 2 layers

Heating Medium: Steam or Oil

Output: 20 Tons materials per 18 hours

When you will need this" Strip drying machine"?

Strand woven bamboo beam/flooring making has its unique process,

1. After steaming of strip/After the carbonizing of bamboo strip, you need this machine to make the the strip dried.

2. After dipping the strip into glue and before presssing them into strand woven beams, you also need this machine.

For one production line, we kindly suggest you to buy 2 SETS of YDDR-55 strip drying machine.

For a better understanding about our whole production line of strand woven flooring making,

,welcome to email us for the product catalogue and pricelist. We will send you very detailed project proposals.

Primary Stage Machine for raw material preparations

Primary Stage Machine for raw material preparations

Raw Bamboo Cutting Machine

Bamboo Splitting Machine

Strip Slicing, Layering, Stranding Machine (bamboo crusher)

Boiling Tank or Carbonization Tank for strip processing.

Glue Dipping Machine

Second Stage of Making Strip into strand woven bamboo furniture boards/block

Second Stage of Making Strip into strand woven bamboo furniture boards/block

Key Machines

1) Strip Drying Machine

2) Hydraulic Press Machine/MaterialLoading Machine/Material unloading Machine/Mould Cavity /Moulds for StrandWoven Beam

3) Solidification Tunnel (BlockCuring Machine)

4) Strand Woven Block Cooling Machine

5) Strand Woven Block Mould Removing Machine

6 ) Two end cutting Machine

7) Side Trimming Machine of Strand woven beam.

8) Multi-blade Dissection Machine (making into 14mm thickness)

9) Sanding Machine

10) Balance Room

3. Flooring Moulding and Coating Lines

3. Flooring Moulding and Coating Lines

FLOORING SHAPE FORMINGMACHINE/COATING LINES/PACKING MACHINE

CHOOSE BESTA, CHOOSE SUCESS.

Our machines have the best quality all over the world. Our strand woven bamboo production lines are applicated in more than 45 factories.The sales of Strand woven bamboo flooring which are made by our production line isabout 0.4 billion every year.

Our newest product line can work normally without repairing for more than one year. We keep innovation all the times.

Our strand woven bamboo machines andtechnology is the best. We are the first company who makes the strand wovenbamboo flooring and develops the market.We have set upfactories in different area in china and foreign countries. We try to make the strand woven bamboo using different kinds of bamboo and in differentareas.So we have rich eaxperiences. The strand woven bamboo products which are madeby our production line and technology can meet industry standards and export standards.We also join in writting the flooring machine industry standards.

We provide good service. We provide the machines, the detailed plan of the Strand woven bamboo flooring product line.(including machines list, Factory design,machines layout drawing and all the things you should prepare),processes and technology, training and good after selling service.

- Previous:BDK-75B 75MM Wooden Ice Spoon Bundling Machine

- Next:Strand Woven Flooring Making Machine, Bamboo Strip Glue Dipping Machine

Home

Home