INTRODUCTION

Strand Woven Bamboo Furniture Board Machine/Strand Woven Bamboo Flooring Making Machine

| Model |

YD12-3600 |

| Name | Strand Woven Bamboo Furniture Board Machine/Strand Woven Bamboo Flooring Making Machine |

| MACHINE SIZE | 2550*2600*5500MM |

| Working Table Size | 2500*1500MM |

| Weight | 80 tons |

| Application |

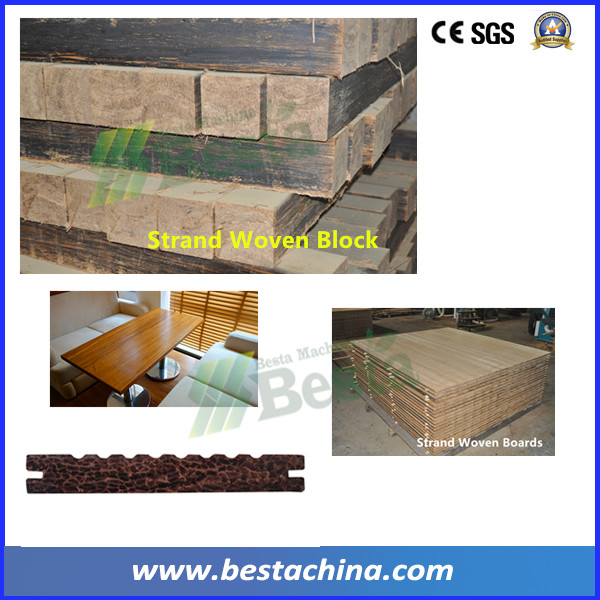

Making Stranded glued bamboo strip into strand woven beam. (3500*140*143mm) |

| Type of Press | Oil hydraulic Press |

| Type of Oil Cylinder | 12 numbers of cylinder |

| Diameter of main oil pipe | 76*8mmm |

| Diameter of Cylinder | 380mm |

| Motor | Two 30KW electric motor and one 5.5 KW motor |

| Main Oil Pump | two 160L plunger pumps |

| Max. Pressure | 3500 Tons |

| Cylinder Stroke | 850MM |

| Electrical Control System | Mitsubishi PLC control systems |

| Capacity | 500 PCS block/day per 20 hours |

| KEY WORD | Hydraulic Press/cold press/strand woven bamboo beam shape forming |

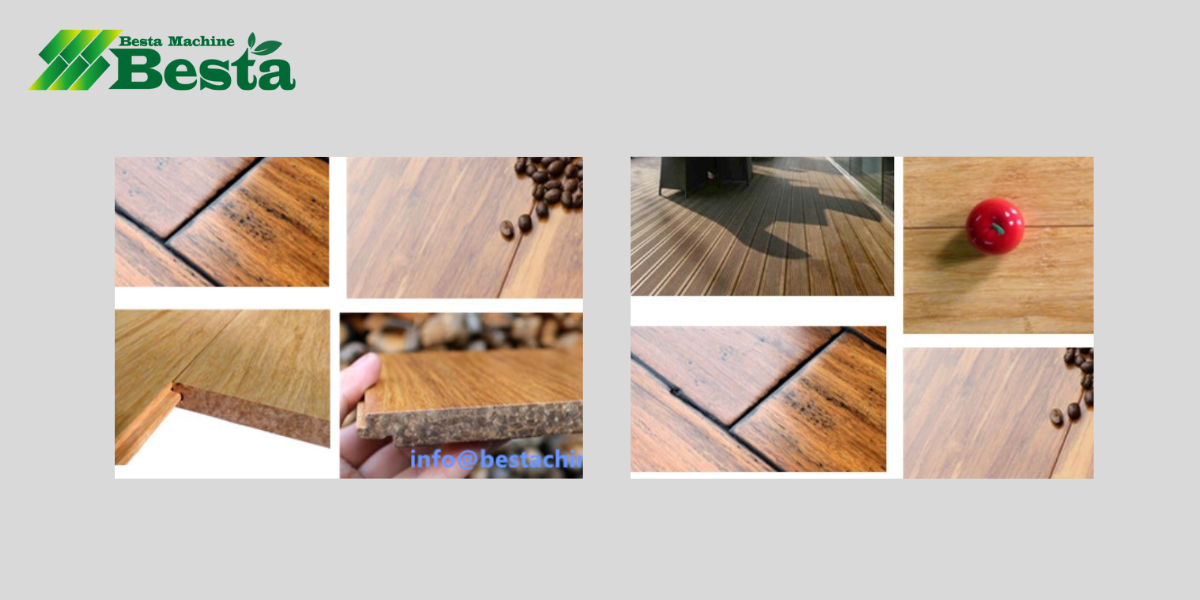

A complete set of Strand Woven Bamboo Flooring Machines

Primary Stage Machine for raw material preparation

Primary Stage Machine for raw material preparation Second Stage of Making Strip into strand woven bamboo furniture boards/block

Second Stage of Making Strip into strand woven bamboo furniture boards/block Flooring Moulding and Coating Lines

Flooring Moulding and Coating LinesSERVICE

Our company Advantages

1. Our machines have the best quality all over the world. Our strand woven bamboo production lines are used more than 45 factories.

The sales of Strand woven bamboo flooring which are made by our production line isabout 0.3 billion every year.

Our newest product line can work normally without repairing for more than one year.

2. Our strand woven bamboo machines and technology is the best.

We are the first company who makes the strand woven bamboo flooring and develops the market.

We have set up more than 45 factories in different area in china and foreign countries. We try to make the strand woven bamboo using

different kinds of bamboo and in different areas. So we have rich experiences.

The strand woven bamboo products which are made by our production line and technology can meet

industry standards and export standards. We also join in making the industry standards.

3. We provide good service. We provide the machines, the detailed plan of the Strand wovenbamboo flooring product line.

(including machines list, Factory design,machines layout drawing and all the things you should prepare),processes and technology,

Welcome to send email for further communications.

Welcome to send email for further communications.

BESTA BAMBOO MACHINE CO., LIMITED.

EMAIL: info@bestachina.com

MOB: 0086 186 5710 6860 (WHATSAPP)

Contact Person: Angel Zhou Wechat ID: ilikechanging

One-stop Service

World Best Strand Woven Bamboo Furniture Board Machine Supplier.

World Best Strand Woven Bamboo Flooring Making Machine Supplier.

MODEL: YD12-3600

Strand Woven Bamboo Beam Press Machine, Oil Press Machine

MACHINE SIZE: 2550*2600*5500MM

Working Table Size: 2500*1500MM

Weight: 80 tons

Application: Making Stranded glued bamboo strip into

strand woven beam. (3500*140*143mm)

Type of Press: Oil hydraulic Press

Type of Oil Cylinder : 12 numbers of cylinder

Diameter of main oil pipe : 76*8mmm

Diameter of Cylinder : 380mm

Motor : Two 30KW electric motor and one 5.5 KW motor

Main Oil Pump : two 160L plunger pumps

Max. Pressure: 3500 Tons

Cylinder Stroke : 850MM

Electrical Control System: Mitsubishi PLC control systems.

Capacity: 500 PCS block/day per 20 hours.

KEY WORKD: Hydraulic Press/cold press/strand woven bamboo beam shape forming.

Primary Stage Machine for raw material preparation

Primary Stage Machine for raw material preparation Second Stage of Making Strip into strand woven bamboo furniture boards/block

Second Stage of Making Strip into strand woven bamboo furniture boards/block Flooring Moulding and Coating Lines

Flooring Moulding and Coating Lines1. Our machines have the best quality all over the world. Our strand woven bamboo production lines are used more than 45 factories.

The sales of Strand woven bamboo flooring which are made by our production line isabout 0.3 billion every year.

Our newest product line can work normally without repairing for more than one year.

2. Our strand woven bamboo machines and technology is the best.

We are the first company who makes the strand woven bamboo flooring and develops the market.

Wehave set up 40 factories in different area in china and foreign countries. We try to make the strand woven bamboo using

different kinds of bamboo and in differentareas. So we have rich experiences.

The strand woven bamboo products which are made by our production line and technology can meet

industry standards and export standards. We also join in making the industry standards.

3. We provide good service. We provide the machines, the detailed plan of the Strand wovenbamboo flooring product line.

(including machines list, Factory design,machines layout drawing and all the things you should prepare),processes and technology,

Welcome to send email for further communications.

Welcome to send email for further communications.

BESTA BAMBOO MACHINE CO., LIMITED.

EMAIL: info@bestachina.com

MOB: 0086 186 5710 6860 (WHATSAPP)

Contact Person: Angel Zhou Wechat ID: ilikechanging

- Previous:BDK-75B 75MM Wooden Ice Spoon Bundling Machine

- Next:BAMBOO BBQ STICK MAKING MACHINE (WHOLE LINE)

Home

Home